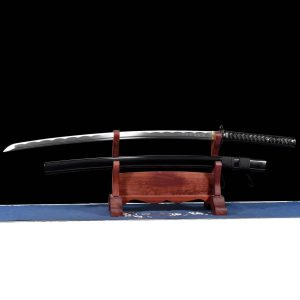

Hand forged 1045 steel T10 burning blade Japanese style command knife

Original price was: $260.00.$248.88Current price is: $248.88.

【 Total length 】 103.0cm 【 Handle 】 26.5cm

【 Blade length 】 71.0cm 【 Blade width 】 3.2cm

[Blade thickness] 0.75cm [Weight approximately] 1.30kg

Description

The hand forged 1045 steel T10 burning blade Japanese style command knife is a sword product that combines traditional craftsmanship with high-quality materials. The following is a detailed introduction to it:

Material characteristics

1045 steel

Medium carbon high-quality steel: 1045 steel is a high-strength medium carbon high-quality steel with good comprehensive mechanical properties. Its carbon content is between 0.43% and 0.50%, which can provide good toughness while ensuring a certain strength. It is suitable for manufacturing swords with certain requirements for strength and toughness.

Processing performance: The cold deformation plasticity is moderate, and the cutting performance under annealing and normalizing conditions is better than that under quenching and tempering conditions. Usually used in a normalized state, when mechanical performance requirements are high, quenching and tempering treatment can be used.

T10 steel

High carbon tool steel: T10 steel is a common high carbon tool steel with a high carbon content of about 0.95% -1.05%. After appropriate heat treatment, high hardness and wear resistance can be obtained, which is suitable for making blade parts to ensure the sharpness and edge retention of the tool.

Good toughness: While ensuring high hardness, T10 steel can also have a certain degree of toughness through appropriate heat treatment processes, making the blade less likely to break when impacted.

Craftsmanship

Forging: Heat 1045 steel and T10 steel separately to the appropriate forging temperature to soften them. Then, the blacksmith repeatedly pounded the steel using tools such as hammers, folding and forging to eliminate impurities inside the steel, refine the grain size, and tightly bond the two types of steel to form a unique forging texture, enhancing the strength and toughness of the blade.

Covering soil and burning blades: This is one of the key techniques in the production process. Firstly, the swordsmith uses a secret recipe to mix clay, charcoal powder, and grinding stone powder to create a burning blade soil, and then evenly applies it to the parts of the blade that need to be protected, such as the back and sides of the blade, leaving the blade exposed. Next, heat the blade to a suitable temperature, usually around 800 ℃, and quickly quench it in water. Due to the slow cooling rate of the soil covering part, it can maintain good toughness, while the blade part cools quickly, resulting in a significant increase in hardness, forming a clear blade line between the blade and the blade. This not only enhances the sharpness and hardness of the blade, but also gives the blade good elasticity.

Grinding: Use grinding stones with different mesh sizes from coarse to fine to grind the blade. Firstly, use a rough grinding stone to remove the unevenness and burrs on the surface of the blade, and then gradually replace with finer grinding stones to finely grind the blade, achieving a mirror like effect on the surface of the blade while maximizing the sharpness and uniformity of the blade. During the grinding process, the sharpener needs to pay special attention to protecting the blade lines to make them clearer and more aesthetically pleasing.

Equipment production and assembly: Handmade tools such as knives, handles, sheaths, etc. Knife stones are generally made of metal materials such as copper, iron, etc., and are decorated with exquisite patterns through carving or casting processes; The handle of the knife is usually made of wooden materials such as cypress wood, and may also be wrapped with fish skin, silk thread, etc. to increase slip resistance and grip comfort; The scabbard is made of wood, with a metal or keratin sheath opening and tail, and some parts are also painted to make it more beautiful and durable. Finally, assemble the blade with the fixture to complete the production of the entire knife.

Performance characteristics

High sharpness: After being burned and finely ground, T10 steel has an incredibly sharp blade that can easily cut various objects and perform well in chopping and stabbing.

Combining rigidity and flexibility: 1045 steel provides the toughness and strength of the blade, while T10 steel ensures the hardness of the blade. The combination of the two allows this blade to withstand a certain degree of impact without breaking, while maintaining its sharpness, achieving a balance of rigidity and flexibility, making it more reliable in use.

Good maneuverability: The reasonable center of gravity design and moderate weight make the Japanese style command knife very flexible when wielded, allowing users to quickly change direction and angle, accurately attack targets, and have good maneuverability whether held with one or both hands, suitable for various swordsmanship techniques.

exterior design

Blade shape: Following the design of traditional Japanese knives, the blade is usually slender with a certain curvature, gradually narrowing from the blade root to the tip. The tip is sharp, and the overall lines are smooth and beautiful. This shape is not only convenient for swinging and chopping, but also has good precision when stabbing.

Size specifications: Generally, the blade length is around 70-80 centimeters, and after adding the handle, the total length is about 100-110 centimeters. The blade width is about 3-4 centimeters, and the blade thickness is about 0.7-0.8 centimeters. However, the specific size may vary depending on the manufacturing process and design style.

Blade pattern and ground muscle: The blade pattern formed by the soil covering and burning process is one of the important features of this knife. The blade pattern has various shapes, such as wavy, straight, and irregular patterns, and each blade pattern is unique. In addition, the texture of the ground muscle formed during the forging process will also appear on the surface of the blade, such as folding patterns, crystallization patterns, etc., increasing the aesthetic and artistic value of the blade.

Reviews

There are no reviews yet.